Updated on October 29, 2021

Refit – July to October 2017

Our refit really began early when we were in Deltaville. Our generator had been spewing black smoke since January to such an extent that it had become unusable. Our trusted generator mechanic, Ken, who had predicted this would eventually become a problem is in Deltaville, so we decided to stay for a few weeks to have it repaired. When we started to investigate, we discovered the generator was overheating again. So first, we had to clear the cooling system again and replace (again) the raw water pump. For a couple of days we (really just Ken) fought a couple of bolts that had welded themselves in place. After that the replacement for the offending elbow went in nicely.

We tested the generator and all was well. As a last step we put antifreeze in the cooling system to protect it from marine growth. I have declared that after spending several thousand dollars on that generator, we will not fix it again. A new one will have to be installed.

While waiting for the generator repair, I was admiring the “stack pack” on the boat next door. A stack pack is a method for storing the mainsail. Another method is a set of lines that go from the mast to the boom that captures the main sail as it falls. I had been using lazy jacks which had been satisfactory but required sail ties to be used to secure the sail, and cover to protect the sail form UV rays. The stack pack captures the sail much better than the lazy jacks, does not require sail ties, and can be fully enclosed by closing a zipper along the top of the stack pack. The advantage is that we can raise and lower the sail easily from the cockpit, which minimizes trips out of the cockpit when underway. We contacted with Ullman Sails for their version of the stack pack which came out very nice.

While we were in Deltaville we also contracted for a set of protective cover (chaps) for our dinghy. The dinghy gets dirty easily and UV affects the fabric. Chaps cover the top to protect the fabric and help keep the dinghy clean. There was no time to finish the job and we will pick them up in the fall when we stop back at Deltaville.

We arrived at Herrington for the refit on July 14 (I sailed the boat while Elena was taking care of the car) and then Elena left for a month in Russia on the 16th. On the 18th, I found a storage shed and got as much stuff off of the boat as I could. On the 21st, we pulled the boat out of the water for a month on land storage (“on the hard”).

While Sophia has air conditioning, it requires sea water to cool the refrigerant. I had bought a RV air condition to augment the onboard air conditioner. Also, the head (toilet) pumps overboard and obviously you can’t do that on the hard Given the heat, the lack of facilities, and climbing a 12-foot ladder to get on and off, I asked a friend at the docks to allow me to sleep on his boat to which he generously acquiesced. Thanks, Igor.

The first job was to arrange for contractor help. I asked Phipps Boatworks to fix the shower drain causing the shower water to back up into the galley sink. I also asked that they refresh the varnish on the bowsprit made and installed last year. And I asked them to fix the refrigerator door which would not close completely and was causing the refrigerator to run constantly, draining the batteries badly. Coupled with the generator problems, this had become a major issue for the operation of the boat. All of this work needed to be done while on the hard and, along with my own work, became the critical path to launch. And we needed to launch before Elena’s return on the August 14th.

The next biggest job was the installation of the new roller-furler for the staysail and the changes to the sail that the roller-furler required, specifically a rope bolt along the front of the sail instead of clamps that attach to the inner forestay wire plus a protective cover sewed into the sail when it is furled. East Coast Rigging could do this work either on the hard or in the water, so no schedule rush.

Download New Staysail Roller Furler Video

Electrically, I asked MTS to change 11 panel lights on the DC power panel and to install a control panel for the propane tanks (something that has been broke for a long time).

After talking to all the folks that were going to do what I would not have time or ability to do, I took the dinghy to Annapolis Inflatables to have a hole repaired. It would be a six week wait until it was repaired but getting it there got me in line to get it done.

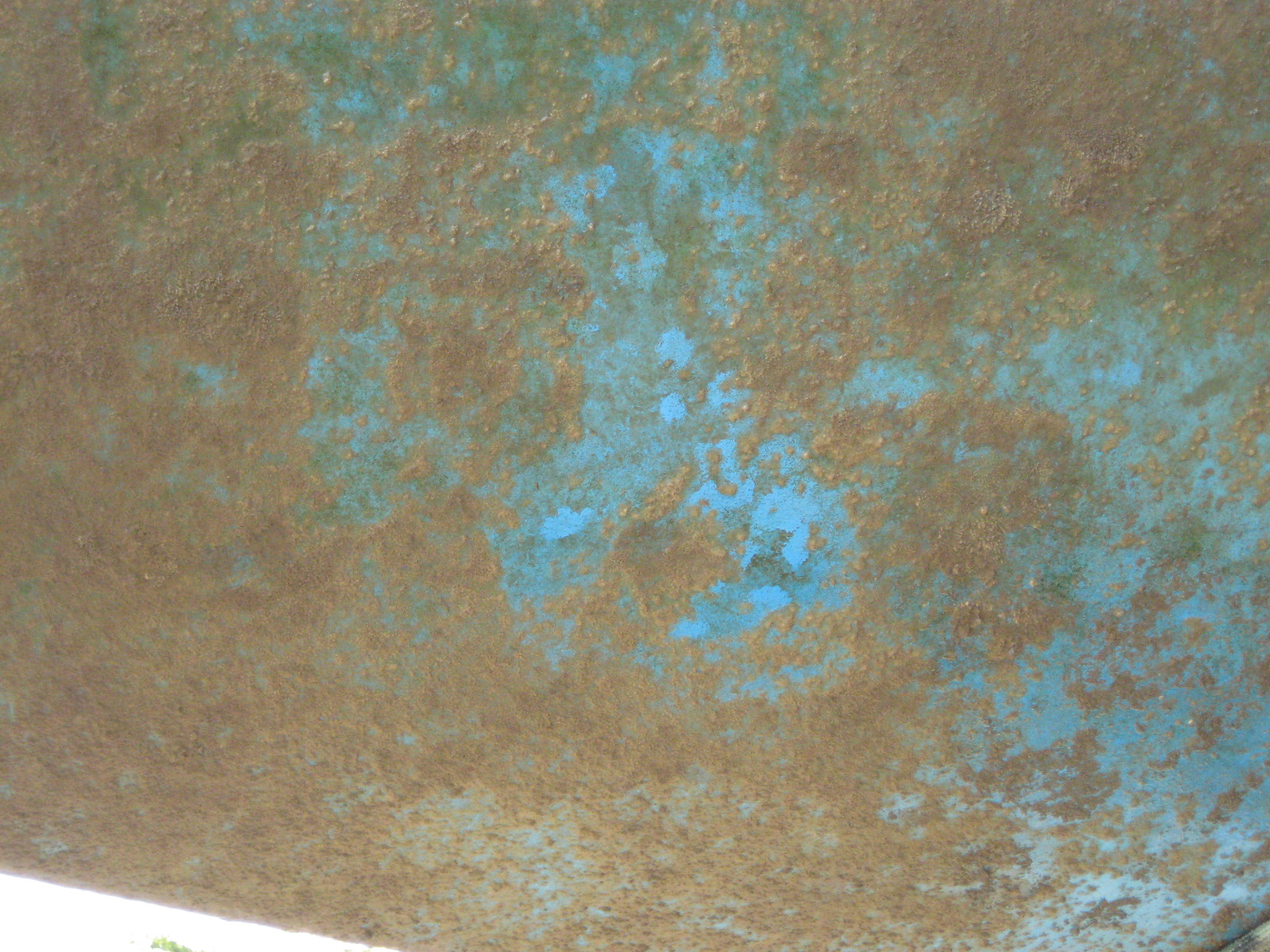

The next thing was to begin to prepare the bottom by sanding the entire hull. The bottom was in fairly good shape with only a couple of blisters. The waterline was a mess and had to be sanded down to bare fiberglass and repainted with a couple of coats of blue paint.

After preparing the hull, I painted it with two coats of Micron Extra (two gallons at $250 a gallon) and I painted the waterline with two coats of the same to try to prevent the mess that we saw at the end of our last cruise. The waterline has become a problem because we have loaded the boat down with so much stuff that we are sitting 3 inches lower in the water than normal and the waterline is frequently in the water and has growth and mud as a result.

After that I put two coats of gloss synthetic varnish (Cetol) on the rub rail that runs the entire length of the boat. This took several days to complete, including taping, sanding, and cleaning the surface. I also cleaned up the scrollwork on the bows and the quarters.

Now that all by work was done, the detailers came by and waxed the entire hull above the waterline, cleaning up streaks and stains and putting a shine hull.

To maintain the varnish on the bowsprit, the anchor platform had to be removed. I did not do anything to platform last year and it was beginning to look weather-beaten. The platform sits right on top of the bowsprit and the beauty of the new bowsprit is hidden by the platform. I began the two-week job of stripping and varnishing the platform with six coats of Cetol (3 natural and 3 gloss). In addition, there were eroded and cracked areas which had to be epoxied. After I had finished, we hoisted the platform aboard (a three-person job) and installed it on a freshly varnished bowsprit. It looks beautiful and the Cetol came close to matching the natural varnish used on the bowsprit.

All the work required for launch was completed by 11 August and we launched on the 13th Elena arrived on schedule on the 14th to Sophia in the water on D Dock just across the water from our old slip on E Dock where we had spent 9 years.

We spent the next two months on a variety of projects. The wood around the cockpit (the coaming) needed to be stripped completely and varnished with six coats of Cetol. The handrails and the dorade (vent) boxes on the cabin top needed the same along with several spots on the cap rail.

The varnish on the interior of the hatches as well as the top of the screens that sit in the hatches had deteriorated. It has been six years since Nick Bazarian and I varnished those hatches so it was not much of a surprise that they needed to be redone. We sanded the hatches clean and the varnish refreshed with 7 coats of natural vanish with 24 hours between coats.

An even bigger job was removing some 200 screws that were exposed on the deck, epoxying and re-drilling the holes, and installing new screws. The deck is getting thin and many of these screws are not useful anymore for holding deck planks in place (they are glued to the deck with some super-strength caulking), but something needs to be used to plug the old holes. After each screw is in place, I then install a teak plug (“bung”) gluing in place with epoxy. After the epoxy dries, I cut each bung with a Dremel and then sand it flush to the deck.

Just after taking out all the screws, I planed the parts of the deck that we are going to caulk, making the deck as even as possible. Over time, water and weather erode the wood on the deck leaving high spots at the seams where the caulk is and ridges in the planks where the soft wood has eroded. I plane and sand will flatten those areas. Elena then tapes the seams and together we caulk the seams using a special teak caulk, removing tape from each section as we finish and trying hard not to step into the we caulk (it has happened more than once). Because of the dust caused when working on the deck, caulking the deck and varnishing are mutually exclusive.

We picked up the dinghy from Annapolis and stowed it in the davits.

We then applied maintenance coats to all the remaining wood including hatch coamings and the cap rail.

We changed the engine oil and filter and both fuel filters on the engine.

As our departure time approached, we brought everything from the shed that we needed back on board Sophia and brought the rest to storage in Stafford including two sails that we can’t or don’t use, one of which is our red, white, and blue spinnaker.

We went through “dock trials” running the engine for 15 minutes plus checking out all of our electronics including our radios, our headsets, our outboard motor for the dinghy, the raising and lowering of the mainsail, and the unfurling and furling of the genoa and staysail. We stocked up on food and topped off our water tanks.

While checking out the electronics, we discovered that the radar was not working. The problem could be fixable, but it is a very old system. We have AIS which gives us visibility and provides us a level of safety with large ships, Recreational boats and shrimpers could be a problem in fog, but the likelihood is low in the areas we are going,

There were some shortcomings in our refit period. We only got to visit Jamie in Richmond once and Jessie in Lynchburg and Jackie in Alexandria not at all. I did visit with Trillion, my former employer twice, but did not get to see any of my former IBM colleagues. I worked almost every day, but will admit it was slow going: all that bending over for the work needed to be done left my back in some discomfort at the end of each day.

On the 7th, we had drinks and eats with Igor and Vika from Jester II (the boat I spend the month on) getting our farewells. Over the next several days, our many of our friends at the marina (Wes and Virginia, Rich Cassano, John Harris, John and Karen who will sail south soon) came by to wish us well.

By October 12th we were ready to go. Farewells had been expressed, the boat was ready, and all the bills had been paid. The weather remains warm so there was no hurry. We chose not to leave on a Friday (considered bad luck by sailors) which was also the 13th (double bad). The winds were not favorable over the weekend and we decided on Tuesday October 17th. On the 16th, we took our truck to the next stopover, Deltaville, renting a car to get us back. We were now ready to head south.